The Paddy separator and the Hamburg whitener, exploit traditional and modern technology and represent a quality guarantee. All the processes carried out at the new Riseria Rizzotti are fundamental to produce a rice of premium quality, original, integral and with a perfect colour.

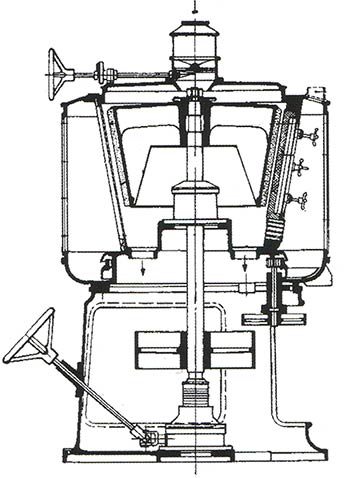

HAMBURG (machine of 1924)

The “Hamburg“ whitener represents perhaps the most prominent application, in the world of the rice-growing, from the well-known artificial stone made from Dressen magnesium cement composed usually of emery and invented in Germany at the end of XIX century. The first “Hamburg“ machines were installed in Italy in 1899 and from that date the whitening technology was constantly improved.

The “Hamburg“ whitener represents perhaps the most prominent application, in the world of the rice-growing, from the well-known artificial stone made from Dressen magnesium cement composed usually of emery and invented in Germany at the end of XIX century. The first “Hamburg“ machines were installed in Italy in 1899 and from that date the whitening technology was constantly improved.

The operative part of the machine is constituted of a trunk of rotating cone in cast iron with a wide base pointing upwards and by a second cone of metal cage statically surrounds the rotating interior. This is enclosed by a metal jacket, which collects the flour produced by the refining.

In the Hamburg then, the threshed rice, is introduced from above and falls on the rotating cone, then the spinning force of gravity pushes it outwards. The grains of rice, pressed onto the external cage move towards the rotating cone covered with Dressen stone, then they have the external first layer removed by the stone’s friction.

This procedure exploits the friction between the grains of rice and the emery stone and generates an increase in temperature inside the machine and, as a result, causing a further loss of dampness in the rice. When the first abrasion operation ends, the refining goes on with a second Hamburg operation through which further external layers of the corn are taken away and so on up to 3 or 4 Hamburg operations until the rice reaches the working degrees require.

For this process knowledge and experience of the operator is fundamental or rather the one who adjusts the machine and manage the settings to obtain the best result possible; it is about an ancient art by now almost lost and tenaciously kept by few irreducible enthusiasts.

The intrinsic art of this operation makes the transformation of the rice long and laborious but it confers qualitative aspects and of final results on in the plate matchless with modern industrial processes.

PADDY machine (1907)

The threshed rice, before the Hamburg machine, must be separated from the wheat still covering the exterior (glumelle, that is to say the outer shell that covers the grain of rice and which are removed during the whitening phase), and therefore the whole product is passed through a machine that since its invention has taken the indo-English name of the brown rice (not worked rough rice) or rather the Paddy separator.

The Paddy consists of a wooden case supported by a metal loom and to which an oscillatory movement is imposed through special gears and pulleys. In the interior the case contains a series of compartments separated by triangular baffles.

The threshed rice and the brown rice fall from the top and are distributed to different compartments; for different processes, they both have a different weight and, as a result, they behave differently on the case of paddy. Particularly, the rough rice that exercises a greater friction tends to go up again thanks to the oscillatory movement of the case, while threshed tends to go down immediately because it exercises an inferior friction.

In this way the selection and separation is made between brown rice, which is guided to the "brahman" for the husk to be removed, and the threshed rice is sent to the Hamburg machine.